The solar energy industry stands at the precipice of a transformative breakthrough as perovskite solar cells shatter efficiency records and prepare for commercial deployment. With LONGi achieving a stunning 34.85% efficiency in April 2025, this “wonder material” is rapidly moving from research laboratories to real-world applications, promising to revolutionize how we harness the sun’s energy.

Inside cutting-edge facilities from Oxford to Shanghai, scientists and engineers are perfecting tandem solar technology that combines traditional silicon with perovskite materials to achieve unprecedented power conversion rates. This quantum leap in photovoltaic efficiency could dramatically reduce electricity costs, accelerate global decarbonization efforts, and unlock revolutionary applications from electric vehicles to spacecraft.

Understanding Perovskite: The Wonder Material Transforming Solar Power

What Makes Perovskite So Revolutionary?

Perovskite refers to a class of synthetic materials with crystal structures mirroring the naturally occurring mineral first discovered in Russia’s Ural Mountains in 1839. Unlike traditional silicon-based solar cells, perovskite materials can be manufactured from readily available elements including bromine, chlorine, lead, and tin.

The material’s revolutionary potential lies in its extraordinary ability to convert a broader spectrum of sunlight into electricity. Perovskite materials can be tuned to take advantage of the parts of the solar spectrum that silicon PV materials can’t use very efficiently, making them ideal partners in tandem solar cell configurations.

Perhaps most remarkably, perovskite films are ultra-thin and can be sprayed or coated onto various surfaces—including windows, vehicle roofs, and flexible substrates. Several companies are currently piloting spray-on perovskite technology that could transform ordinary windows into power-generating surfaces.

The Science Behind Superior Efficiency

The key to perovskite’s superior performance lies in the high mobility of electrons within the cells, combined with excellent light absorption properties. While conventional silicon panels typically achieve efficiencies of 21-23%, their theoretical maximum hovers around 33%—a limitation known as the Shockley-Queisser limit.

By stacking perovskite layers atop silicon cells in tandem configurations, manufacturers can smash through this barrier. The theoretical maximum efficiency for perovskite-silicon tandem cells exceeds 47%, opening vast new frontiers for solar energy capture.

Record-Breaking Achievements: The Race to Maximum Efficiency

LONGi’s Historic 34.85% Milestone

In a landmark achievement that signals perovskite technology’s commercial viability, Chinese solar manufacturer LONGi revealed it achieved 34.85% power conversion efficiency for a two-terminal tandem perovskite solar cell, certified by the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL). This represents the first certified efficiency exceeding the single-junction Shockley-Queisser limit for double-junction tandem cells.

LONGi’s breakthrough builds on its previous record of 34.6% set in September 2024. The researchers achieved this through better structural coupling between the perovskite top cell and the crystalline silicon bottom cell using a patented asymmetric textured surface technology.

All-Perovskite Tandems Push Beyond 31%

While silicon-perovskite combinations dominate headlines, all-perovskite tandem cells are also advancing rapidly. SolaEon Technology announced its all-perovskite tandem solar cell achieved 31.38% certified conversion efficiency with 30.7% stabilized maximum power point tracking (MPPT) efficiency, setting a global record for this cell configuration.

Research published in Nature Materials demonstrated all-perovskite tandem solar cells achieving over 29% efficiency with improved crystal orientation, addressing critical challenges in wide-bandgap perovskite subcells that previously limited performance.

Laboratory Breakthroughs Continue Accelerating

The pace of innovation shows no signs of slowing. A team of Chinese researchers achieved 34.58% power conversion efficiency using a novel self-assembled monolayer (SAM) design called HTL201, which enables more uniform perovskite film formation and enhanced photon absorption.

For flexible applications, researchers demonstrated flexible perovskite/silicon tandem solar cells achieving 29.88% efficiency by ensuring high phase homogeneity to promote charge transfer and release residual stress. This breakthrough opens possibilities for portable, lightweight solar solutions.

Oxford PV Leads Commercial Deployment Revolution

From Laboratory to Solar Farms

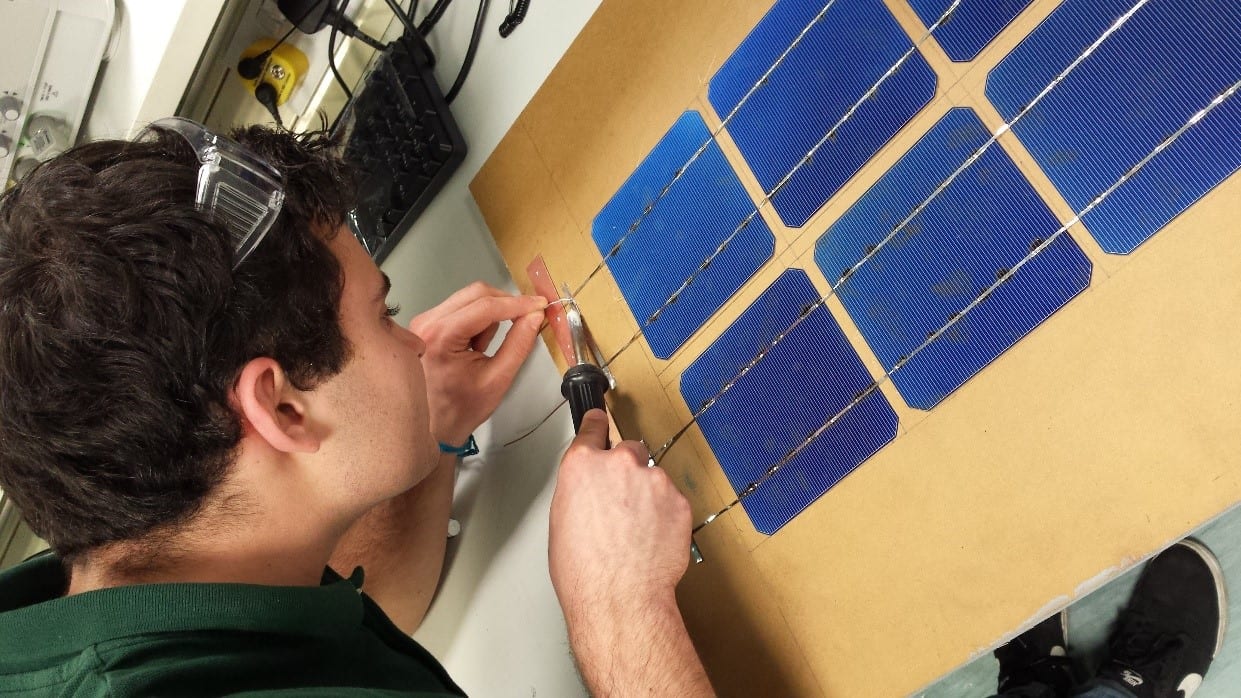

Oxford PV, a spinout from Oxford University, exemplifies how perovskite technology is transitioning from research to real-world deployment. The company operates a state-of-the-art testing facility where sample solar cells undergo rigorous evaluation including electron microscopy for impurity detection and spectral response measurement.

In 2024, Oxford PV set a residential-size module record achieving 26.9% conversion efficiency. The company believes its research program will continue improving cell efficiency by approximately one percentage point annually.

Critically, Oxford PV has moved beyond laboratory demonstrations. In September 2024, the UK-based company shipped their tandem 72-cell panels to the United States for a utility-scale installation, with modules achieving 24.5% efficiency. The company plans to scale production to gigawatt levels.

Real-World Testing and Performance Validation

Oxford PV recently deployed approximately 100 kilowatts of tandem solar panels—enough to power around 14 average US households—to a commercial solar farm in the United States. These modules report 24.5% efficiency, and their real-world performance is being closely monitored across multiple climate zones.

Chief Executive David Ward emphasizes the importance of field testing: “We want our panels tested in multiple different parts of the world so we can build a dataset of performance.” This comprehensive approach addresses concerns about how perovskite technology performs under varying environmental conditions.

Accelerated Aging: Simulating Decades in Weeks

Inside Oxford PV’s environmental chambers, test cells endure “accelerated aging tests” exposing them to extreme heat, humidity, and rapid temperature cycling. According to Laura Miranda, Oxford PV’s head of sustainability, “These tests give an idea of how the cells could degrade in the field under various conditions without having to wait five, 10 or 15 years.”

The company designs its panels for recycling using the same processes as standard silicon panels, addressing concerns about the small amounts of lead contained within perovskite materials.

Tackling Critical Challenges: Durability, Stability, and Toxicity

The Moisture and Heat Sensitivity Concern

Perovskite’s Achilles’ heel has traditionally been susceptibility to moisture and elevated temperatures. Early perovskite products degraded far more quickly than silicon counterparts, raising questions about long-term commercial viability.

Field tests of metal halide perovskite solar minimodules in Belgium and Cyprus showed performance loss rates between 7-8% per month, though the most durable minimodule maintained 78% of initial efficiency after one year. These results underscore both progress made and challenges remaining.

Joseph Berry, a researcher at NREL, notes the fundamental difficulty: “Manufacturers of silicon modules can guarantee 30-year lifetimes because they’ve got 30 years of field data. But for perovskites, knowing that the module we’re making today is going to last 30 years is a really hard material science question.”

The Lead Toxicity Debate

The presence of lead in perovskite cells has generated controversy and scrutiny. Critics worry about health and environmental impacts, particularly during manufacturing and disposal.

However, Berry emphasizes context matters: “When compared with the energy output of the panels, the scale of lead used is tiny, and much lower than for the same amount of energy produced by burning coal.” He argues that properly designed recycling and reuse processes can mitigate toxicity concerns.

Oxford PV and other manufacturers are developing recycling protocols that handle perovskite panels similarly to silicon panels, which also contain lead. The broader solar industry is collectively addressing end-of-life panel management as deployment scales.

Manufacturing and Environmental Impact Considerations

One study found perovskite tandem technology has up to 7% higher environmental impact per panel than normal silicon solar PV due to extra manufacturing processes. However, the increased energy output more than compensates for this, since fewer panels are needed for equivalent electricity generation.

The development of non-toxic alternatives continues advancing. Researchers have created tandem solar cells combining chalcogenide perovskite (a non-toxic material) and silicon, improving efficiency by 38%, demonstrating pathways toward eliminating lead entirely.

Economic Analysis: Cost Competitiveness and Market Potential

The 10% Cost Reduction Promise

Oxford PV’s internal analysis suggests tandem perovskite panels could reduce electricity costs by approximately 10% compared to standard silicon panels through their ability to generate more power over the same area.

Research from NREL found that tandem modules must achieve at least 25% efficiency to be price competitive with other solar technologies. With commercial products already surpassing this threshold, the economic case strengthens considerably.

NREL researcher Jacob Cordell notes: “A 2.5% absolute efficiency gain in a module provides the same reduction in cost per nameplate capacity as doubling the size of your factory”. This finding highlights efficiency improvements’ outsized impact on manufacturing economics.

Historical Cost Trajectory and Market Positioning

When tandem panel discussions began in the late 2000s, industry skepticism ran high. David Ward recalls: “Putting two cells together to absorb more sunlight has been known in the past, but it has been very expensive. A combination called gallium arsenide works on the same principle, but it’s significantly more expensive than silicon.”

Perovskite technology’s revolutionary promise lies in achieving gallium arsenide-like performance at silicon-like costs. As manufacturing scales and processes optimize, cost advantages should continue improving.

Global Competition: China, US, and International Players Race Ahead

Chinese Manufacturers Dominate Record-Breaking

China’s solar giants are moving aggressively into perovskite tandem technology. Beyond LONGi’s record achievements, Shanghai-based Longi claims it has achieved 33.9% efficiency for a single cell, while Oxford PV has signed licensing deals enabling technology deployment in China’s massive domestic market.

In December 2024, Korea-based Qcells reported a new world record for large-scale solar panels, reaching 28.6% efficiency on a full-area M10-sized (330.56 cm²) tandem solar cell scalable for mass manufacturing.

American Innovation and Commercial Push

US-based companies are pursuing diverse commercialization strategies. Swift Solar, a spinout from MIT and Stanford, announced a pilot with American Tower Corporation to deploy perovskite tandem panels across 42,000 telecommunications towers—a massive real-world testing ground.

Boston-based CubicPV and NREL have achieved 24% efficiency in tandem cells, while Caelux recently completed its first commercial shipment of Active Glass perovskite technology.

Scott Graybeal, Caelux’s chief executive, acknowledges: “The real value here is how much energy are you going to produce over the term of a power purchase contract. That’s what folks care about.”

Japanese Precision Engineering

In Japan, Kyoto University spinout EneCoat Technologies achieved 30.4% efficiency for its perovskite-silicon tandem solar cell, developed in partnership with Toyota Motor Corporation using a proprietary low-temperature deposition process.

This collaboration with a major automotive manufacturer signals interest in vehicle-integrated photovoltaics—a promising application for high-efficiency tandem cells.

Revolutionary Applications: Beyond Rooftops and Solar Farms

Electric Vehicle Integration: Solar-Powered Cars Emerge

Automotive applications represent one of perovskite technology’s most exciting frontiers. Higher efficiency makes vehicle-integrated solar panels increasingly practical.

Graybeal explains: “You can’t run a vehicle solely off solar because it’s a lot of weight to push around, but providing a trickle charge to the battery to give a little extended range is absolutely a possibility.” Caelux is in discussions with major automotive manufacturers about testing their products.

Oxford PV’s Ward adds: “Cars are mostly sat in the open for big chunks of the day—why would you not want to harvest that power?” Even modest solar contributions could extend electric vehicle range by tens of miles daily, reducing charging frequency and range anxiety.

Space Applications: Powering the Satellite Revolution

Tandem perovskite panels are attracting intense interest for space applications, particularly powering satellites. Traditional space solar panels use gallium arsenide due to superior efficiency and radiation tolerance compared to silicon.

Perovskite tandems deliver comparable benefits at dramatically lower costs—crucial for the proliferation of cheaper satellites with shorter lifespans being launched today. Ward notes Oxford PV is “talking to a number of people” about space applications, though development remains in early stages.

Building-Integrated Photovoltaics: Windows That Generate Power

Perovskite’s unique properties enable building-integrated photovoltaic solutions impossible with silicon. Ultra-thin perovskite films can be sprayed onto windows and facades, transforming building exteriors into electricity-generating surfaces.

Multiple companies are piloting spray-on perovskite window technology. While standalone perovskite cells may not match tandem efficiency, their versatility enables applications where traditional panels are impractical.

For detailed information about emerging solar technologies, visit the National Renewable Energy Laboratory.

Expert Perspectives: Challenges and Future Outlook

The Field Data Imperative

Joseph Berry emphasizes that real-world performance data remains critical: “It’s one thing to think that you’ve got something durable, but it’s another to show it out in the field. While we expect the perovskite to be what really drives a lot of the different aspects of performance out in the real world, we need to see that.”

The gap between laboratory “champion cells” and mass-manufactured panels also requires attention. Tsutomu Miyasaka, whose team first used perovskites for solar power in 2009, notes that records achieved for lab-made cells generally represent exceptional samples that perform better than larger factory-manufactured panels, where quality can be inconsistent over large areas.

The Inexorable Shift to Tandem Technology

Despite challenges, industry leaders express confidence in perovskite’s trajectory. Scott Graybeal admits things are “just at the start” but believes the solar sector is “inexorably shifting” to tandem technology. “It’s going to be utterly transformational,” he predicts.

David Ward notes historical skepticism has given way to mainstream acceptance: “When discussion on them started in the late 2000s, tandem panels were initially met with scepticism in the industry, with many believing they were simply too good to be true.”

NREL research indicates that the next steps for commercialization involve improving reliability in field conditions and scaling high-efficiency devices to full module sizes while maintaining performance.

Solar Power’s Explosive Growth Context

The Renewable Energy Tipping Point

Solar power now accounts for nearly 7% of global electricity generation and is rising dramatically—growing 29% in 2024 alone. It has become the second-cheapest new electricity source globally (only onshore wind is cheaper).

A 2023 analysis found solar technology’s trajectory may have already reached a tipping point toward dominating global electricity markets, even without further climate policies. Perovskite tandem technology could accelerate this transition by making solar even more cost-effective.

Silicon’s Efficiency Ceiling Drives Innovation

Conventional silicon panels dominate today’s market but face fundamental efficiency limitations. Silicon-only cells typically achieve 21-23% efficiency, with theoretical maximum around 33%. Expanding renewable energy at the scale needed for global decarbonization requires producing maximum energy for minimum cost—making efficiency paramount.

For comprehensive solar market analysis and updates, consult PV Magazine.

Manufacturing Scale-Up: From Pilot Projects to Gigawatt Production

Current Production Capabilities

Oxford PV is manufacturing cells at a factory in Germany, representing a crucial step from laboratory to industrial production. The company aims to scale to gigawatt-level output—sufficient to power millions of homes.

Multiple manufacturers worldwide are building production capacity. Increasing module efficiency and expanding manufacturing capacity play complementary roles in reducing costs, with each cost lever playing similar roles depending on manufacturers’ ability to scale up and improve module performance.

Quality Control and Consistency Challenges

Maintaining laboratory-level efficiency at factory scale presents significant challenges. Miyasaka warns that champion cells’ performance often exceeds what manufacturers can achieve consistently across large production runs.

Berry highlights that data companies claim in commercial spec sheets represents more realistic performance expectations: “If they’re able to close the gap between this and their record, that is meaningful.”

Investment and Economic Incentives

Major financial institutions recognize perovskite’s potential. David Ward mentions: “Jamie Dimon said that JPMorgan is going to get into the business. They’re going to be lending. They’re probably set up some kind of an exchange.”

The U.S. Department of Energy’s Solar Energy Technologies Office is funding extensive perovskite research through NREL and other institutions, accelerating commercial development.

Technical Innovations Driving Performance

Self-Assembled Monolayers and Interfacial Engineering

Recent breakthroughs in interfacial engineering have driven efficiency gains. Researchers developed techniques for perovskite molecules to self-assemble on transparent oxide layers, creating denser, more uniform monolayers that enable stronger perovskite film interaction.

These self-assembled monolayer designs exhibit low parasitic absorption (maximizing photons available for energy production) and rapid charge extraction capabilities—both critical for high efficiency.

Crystal Orientation and Phase Homogeneity

Research published in Nature Materials revealed that improved (100) crystal orientation in wide-bandgap perovskites suppresses non-radiative recombination. Scientists achieved this through surface composition engineering using two-dimensional perovskite intermediate phases.

For flexible devices, ensuring high phase homogeneity promotes charge transfer across all facets of textured substrates and releases residual stress at interfaces—enabling both high efficiency and mechanical stability.

Advanced Manufacturing Processes

Chinese and French scientists combined slot-die coating strategies with pyrrodiazole additives to immobilize lead and formamidinium iodides, achieving 10 cm × 10 cm inverted perovskite solar modules with 20.3% certified efficiency and 94% efficiency retention after 1,000 hours at 65% humidity.

Indian Institute of Technology researchers introduced novel NiO/Ag/NiO transparent electrodes using low-energy physical vapor deposition, achieving exceptionally low electrical resistance and high visible light transmittance.

Environmental and Sustainability Considerations

Life Cycle Analysis and Carbon Footprint

While perovskite tandem panels require additional manufacturing processes that increase per-panel environmental impact, their superior efficiency more than compensates. Fewer panels needed for equivalent power generation reduces overall material consumption, transportation costs, and installation labor.

As manufacturing processes optimize and scale economies emerge, environmental impacts per watt of electricity generated should decrease further.

Recycling Infrastructure Development

The solar industry broadly recognizes the need for comprehensive end-of-life management strategies. As first-generation solar panels approach retirement age, recycling infrastructure is expanding.

Perovskite manufacturers are designing products compatible with existing silicon panel recycling processes, enabling industry-wide solutions rather than technology-specific approaches.

Water and Resource Consumption

Perovskite materials can be manufactured from abundant elements without rare earth requirements. This contrasts favorably with some other advanced solar technologies dependent on scarce materials with concentrated geographic availability.

Water usage during manufacturing and potential contamination risks require ongoing attention as production scales.

Policy and Regulatory Landscape

Government Support for Innovation

The U.S. Department of Energy’s substantial funding through NREL and other programs demonstrates governmental recognition of perovskite technology’s strategic importance. Similar support exists in China, European Union nations, and other countries competing for renewable energy leadership.

Tax incentives, research grants, and deployment subsidies will influence commercialization pace and geographic distribution of manufacturing capacity.

Safety Standards and Certification Requirements

Regulatory frameworks for solar panel safety, performance guarantees, and disposal requirements continue evolving. Perovskite manufacturers must navigate certification processes that evolved around silicon technology.

NREL’s role in certifying efficiency records provides independent validation crucial for investor and consumer confidence.

Investment Opportunities and Market Forecasts

Venture Capital and Strategic Investment

Perovskite startups have attracted significant venture capital and strategic investment from established energy companies, construction firms, and automotive manufacturers recognizing technology’s disruptive potential.

Oxford PV, Swift Solar, Caelux, and others have collectively raised hundreds of millions in funding to scale operations and accelerate commercialization.

Market Size Projections

While precise market forecasts vary, analysts project tandem perovskite technology could capture significant solar market share within the next decade if durability and cost targets are met.

The global solar market’s explosive growth provides enormous opportunity—even modest market penetration translates to multi-billion dollar industries.

For current renewable energy market analysis, visit the International Energy Agency.

Consumer Perspective: What Homeowners Should Know

When to Consider Upgrading

Homeowners with existing solar installations should not rush to replace functioning systems. However, those planning new installations or facing roof repairs should evaluate whether waiting for tandem perovskite products makes financial sense.

Cost-Benefit Analysis

Higher upfront costs for more efficient panels may be justified by reduced installation costs (fewer panels needed), smaller roof space requirements, and higher long-term electricity generation.

Warranty and Longevity Questions

Prospective buyers should carefully evaluate manufacturer warranties and performance guarantees. Questions about 25-30 year reliability remain open for perovskite technology, though confidence is growing rapidly.

Conclusion: The Dawn of Solar Energy’s Next Chapter

Perovskite solar cell technology stands at a pivotal moment—transitioning from laboratory curiosity to commercial reality. With certified efficiencies reaching 34.85% and multiple manufacturers deploying pilot installations worldwide, the technology’s potential appears increasingly tangible.

Critical challenges remain, particularly proving long-term durability in diverse environmental conditions and achieving consistent quality at manufacturing scale. However, the pace of innovation and level of investment suggest these obstacles will be progressively overcome.

As Joseph Berry emphasizes, field performance will ultimately determine success: “While we expect the perovskite to be what really drives a lot of the different aspects of performance out in the real world, we need to see that.”

For consumers, businesses, and policymakers, perovskite tandem technology represents a probable—not merely possible—future for solar energy. The question is no longer whether this wonder material will transform the industry, but rather how quickly the transformation will occur and who will lead it.

As solar power continues its exponential growth trajectory and renewable energy becomes increasingly essential for climate change mitigation, every percentage point of efficiency improvement and every dollar of cost reduction accelerates humanity’s transition to sustainable energy systems.

The perovskite revolution may have begun in research laboratories, but its impact will be felt on rooftops, solar farms, vehicles, and satellites worldwide—ushering in solar energy’s most transformative era yet.

Comments